{ "@context":"http://schema.org", "@type": "BlogPosting", "image": "https://sewingempire.com/wp-content/uploads/2021/02/sewing-machine-keep-jamming.png", "url": "https://sewingempire.com/why-does-my-sewing-machine-keep-jamming/", "headline": "Why Does My Sewing Machine Keep Jamming?", "description": "When your sewing machine keeps jamming while stitching, common reasons are feed dog, bobbin thread & presser foot. Read article for detail.", "dateCreated": "2021-02-25", "datePublished": "2022-12-19", "dateModified": "2022-12-19", "isFamilyFriendly": "true", "copyrightYear": "2023", "copyrightHolder": "Sewing Empire", "accountablePerson": { "@type": "Person", "name": "Henry Leo" }, "author": { "@type": "Person", "name": "Henry Leo" }, "creator": { "@type": "Person", "name": "Henry Leo" }, "publisher": { "@type": "Organization", "name": "Sewing Empire", "url": "https://sewingempire.com/", "logo": { "@type": "ImageObject", "url": "https://sewingempire.com/wp-content/uploads/2020/10/Sewing-Logo.jpeg", "width":"500px", "height":"108px" } }, "mainEntityOfPage": "True", "keywords": [ "Why Does My Sewing Machine Keep Jamming", "My Sewing Machine Keeps Jamming", "Bobbin Thread Keeps Jamming", "My Sewing Machine Is Jammed", "Brother Sewing Machine Keeps Jamming", "Sewing Machine Keep Jamming", "Sewing Machine Jamm ", "Reasons For Sewing Machine Jamming", "Sewing Machine Jamming Reasons" ], "genre":["SEO","JSON-LD"], "articleSection": "Blog" }

When your sewing machine keeps jamming while stitching, common reasons are feed dog, bobbin thread & presser foot. Read the article for detail.

Do you own a sewing machine that keeps jamming in the middle of stitching? Well, that’s the problem faced by every person associated with stitching.

Especially for the newbies, it seems hard to tackle the jamming problem due to the lack of knowledge about handling stitching.

However, this article can be extremely helpful to solve the jamming problem at home without taking it to the mechanic.

Especially if you are new to the field, get ready to explore a solution-based piece of the article that deals with why your sewing machine keeps jamming?

Technical Reasons For Sewing Machines Jamming

Here you will be given an insight into common jamming problems that you can instantly troubleshoot,

1. Feeding Dog

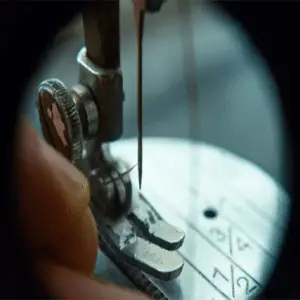

Feeding dog is a component in a sewing machine that comes with tiny teeth.

These teeth are responsible to drag the cloth piece inside the machine for stitching purposes.

If your machine is jammed that is probably due to the low feed dog. Or there must be debris, dust, or trash in the feed dog. That’s why it’s important to maintain a stitching machine.

2. Presser Foot

Another important thing that comes after a feed dog is the level of the presser foot.

Make sure that your presser foot should have the same level compared to the feed dog.

This is because a presser low presser foot creates a hurdle for the fabric to be smoothly moved around.

3. Bobbin Thread

The working component of the sewing machine includes two threads going through the fabric. The thread goes through the needle from a spool, and the other one comes from the bobbin.

At the point when the needle brings down, it keeps the lower thread while going through the fabric. The needle starts to lift and structures a circle of yarn under the fabric.

This component can be complicated and can mess up your sewing machine.

Other Reasons For Sewing Machines Jamming

Besides having such technical issues following are the reasons why your machine can cause you occasional jamming.

1. Skipping Of Stitches Causes Machine Jamming

This happens when you are using an inappropriate needle type. Needles are of unlimited types and designs to meet the variety of fabrics. If the fabric you are stitching is knitted, it’s better to use a ballpoint needle.

On the other hand, if the fabric is woven then use a sharp needle to avoid jamming issues. Another reason that keeps the process jammed is when your needle is bent.

A bent in a needle happens when the fabric is forced to penetrate inside the feed dog.

2. Tangling Of Thread Causes Machine Jamming

Tangling is another reason for the constant jamming of the sewing machine.

Hence, it’s important to understand the causes behind tangling that will ultimately help you troubleshoot machine jamming.

However, beginners usually confuse the tangling issue with a bobbin. The reason behind tangling is when the tailor keeps the presser foot down while threading the sewing machine.

This involves pressure foot or becomes excessively tight, in this way it prevents the thread from settling appropriately between the plates.

3. Poor Quality Thread

There are many types of sewing threads available in the market. Sometimes, intentionally or unintentionally we tend to feed our sewing machines with low-quality threads.

However, saving money is not a bad idea but sometimes poor quality thread may end up in the form of jamming machines.

A poor quality thread produces lint that ultimately gets inside the machine parts and the excessive amount of lint becomes a reason that could jam your machines.

Besides this, the low-quality thread seems to have been weaker in quality which may cause you constant break of thread during the process.

Hence, it’s always important to make sure that the thread you are using should have good quality.

3. Clog Causes Machine Jamming

Clog becomes in your machines especially when you have constant stitching projects. Clogging often occurs in machines when you constantly do stitching without proper cleaning and maintenance.

Thread and fabric lint get into machines and after some time they keep the internal components jammed and become a hurdle for the smooth running of the machine.

Hence it is always important to clean the components of your machine and grease them properly.

4. Thread Treatment

The machine contains two types of threads, the Bobbin thread and the upper thread spool that we pass through the needle’s eye. We do some common messes while treating them that ultimately come in the form of jamming.

First of all, keep a longer bobbin thread while passing the upper thread through the needle eye. Because a shorter length is sometimes stuck inside the machine.

Besides this, while stitching fabric place the fabric from one or two-inch away from the edges. That causes the needle to pull down the fabric with it and that results in knotting and jamming.

Conclusion

Jamming is a problem that needs to be done ASAP. However, following these troubleshoots you can solve the jamming on your own.

But in some situations when their internal components deteriorate, chances are you will have to bring your machine to a professional mechanic. To avoid this, keep proper maintenance and cleaning of your machine.

Check Out These Posts Too!

Robert Patricia

Robert Patricia is a data analytic and content creator. He has worked extensively with large data sets to glean insights for both public and private sector clients. He has used this knowledge to create compelling content for brands across the internet. Albert also enjoys creating content for websites and social media. He is an expert at creating catchy headlines and understands how to capture the attention of readers.